Grain Refiner

Grain Refiner-SPL(06) is a specialized chemical-based compound developed for Aluminium Extrusion Industries to refine the grain size of molten aluminium and remove dissolved hydrogen gas. With this advanced formulation, there is no need for separate degassing or nitrogen purging, saving both time and resources during the casting process.

Product Composition and Usage

- Base: Chemical Salts

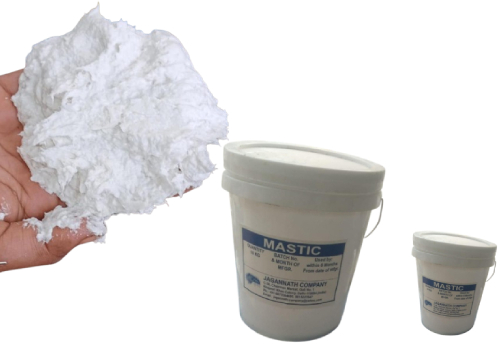

- Appearance: Off white colour

- Addition Rate: 1 Kg per 1000 Kg molten metal

- Usage: Dip the tablets at the bottom of the charged furnace

- Packing: 35 Kg Box

- Each Packet Weight: 1 Kg approx. (Contains 4 Tablets)

Key Benefits of Grain Refiner-SPL(06)

- Eliminates Need for Degassing/Nitrogen: Saves 15–20 minutes per casting cycle.

- Enhanced Surface Finish: Increases shine in billets and section profiles.

- High Reactivity: Creates rapid bubbling to lift out impurities and dross efficiently.

- Odour-Free Process: Unlike ordinary grain refiners, it produces no unpleasant smell.

- Optimized for Light Sections: Proven effective on sections up to 600 grams; improves press speed and quality. (Recommended 2 Kg per 1000 Kg for light profiles)

- Cost-Efficient: Reduces the need for Titanium Rods and separate degassing chemicals.

- Performance Improvement: Trial usage over a month shows improved section quality and enhanced extrusion speeds.

Application Areas

- Aluminium Extrusion Billets

- Section Profiles for Architectural and Industrial Use

- Foundry Operations Focused on Grain Refinement

Why Choose Jagannath Company?

- Proven Product Innovation: Designed for real-world operational efficiency.

- Quality Assured: Manufactured under expert metallurgical supervision.

- Field Tested: Practical benefits validated across leading extrusion plants.

Contact Us

Company: Jagannath Company

Email: jagannath.company@yahoo.com

Phone: +91-98733 84650