Coatings

Jagannath Company presents an extensive range of Coatings designed to enhance the performance, longevity, and efficiency of aluminium melting, casting, and foundry operations. Our specialized coatings protect refractories, improve surface finish, and reduce energy consumption in high-temperature processes.

Advanced Protection with High-Performance Coatings

Our coatings are engineered for optimal thermal insulation, oxidation resistance, and surface smoothness in demanding aluminium and non-ferrous metal processing environments. They reduce build-up, enhance refractory life, and ensure superior casting quality.

Holecote

Holecote is a premium coating designed for the protection of tapping holes and launders in aluminium furnaces. It forms a durable, non-wetting layer that resists metal penetration and minimizes maintenance downtime.

- Usage: Applied to furnace tapping holes, launders, and troughs handling molten aluminium.

- Key Benefits: High-temperature resistance, anti-wetting properties, and prolonged refractory life.

- Best For: Aluminium foundries and melting plants looking to minimize metal adhesion and improve furnace performance.

Refcote

Refcote is a versatile refractory coating formulated for the protection of furnace walls, ladles, and other high-temperature contact surfaces. It ensures a smooth, non-reactive barrier that enhances thermal efficiency and reduces erosion.

- Usage: Coating for ladles, crucibles, furnace walls, and casting equipment.

- Key Benefits: Excellent adhesion, reduced energy loss, and superior surface finish in molten metal applications.

- Best For: Aluminium extrusion, casting, and remelting operations requiring enhanced thermal insulation.

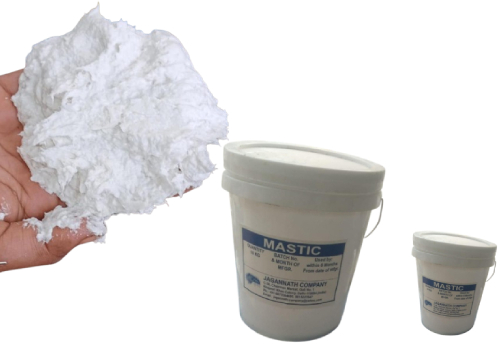

Chalk Powder

Chalk Powder is a fine-grade refractory powder used as a release agent and parting compound in casting operations. It provides a smooth, non-stick barrier that facilitates easy metal release and minimizes casting defects.

- Usage: Dusting of mould surfaces, casting tables, and metal contact points.

- Key Benefits: Non-reactive barrier, improved casting finish, and reduced sticking of molten metal.

- Best For: Foundries, die casting units, and gravity casting setups.

Teracote-43(M)

Teracote-43(M) is a high-performance refractory coating specially formulated for extreme temperature applications. It offers exceptional thermal shock resistance, reduced oxidation, and improved surface integrity in metal processing environments.

- Usage: Coating of ladles, furnace linings, and casting equipment subjected to high thermal loads.

- Key Benefits: Enhanced thermal insulation, excellent bonding to refractory surfaces, and extended equipment life.

- Best For: Aluminium foundries, remelting plants, and high-temperature casting applications.

Key Features of Our Coatings:

- Thermal Protection: Advanced formulations providing excellent heat resistance and insulation.

- Surface Enhancement: Smooth, non-stick finishes that reduce metal adhesion and buildup.

- Versatile Applications: Suitable for a wide range of aluminium processing and foundry equipment.

- Custom Formulations: Available to match specific process requirements and equipment setups.

Customization Options

We offer coatings in various formulations, packaging, and application methods to suit customer-specific needs. Technical support is available for selecting the best product and optimizing coating performance in different metallurgical environments.

Application Areas:

- Aluminium Melting Furnaces

- Launders, Troughs, and Tapping Systems

- Foundries and Casting Units

- Refractory Lining Maintenance

Optimize Your Process with Advanced Coatings

Jagannath Company’s range of coatings ensures superior thermal protection, improved casting quality, and extended equipment life in aluminium processing environments. Trust us for high-quality, reliable solutions.

Contact Us

Company: Jagannath Company

Email: jagannath.company@yahoo.com

Phone: +91-98733 84650