Cover Fluxes

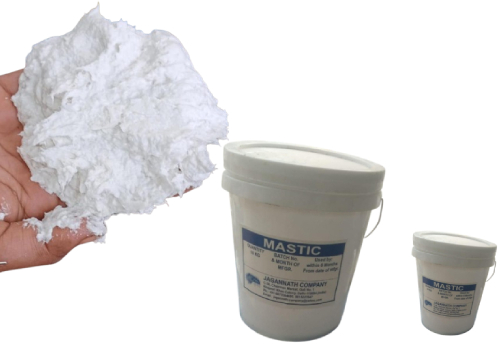

Jagannath Company offers a premium range of Cover Fluxes specifically formulated to protect molten aluminium from oxidation, gas absorption, and contamination during melting and holding operations. Our fluxes are engineered for high efficiency, easy application, and excellent performance across various alloy compositions and furnace types.

Advanced Protection for Molten Aluminium

Our Cover Fluxes act as a barrier between the molten metal and the atmosphere, preventing oxidation and minimizing metal loss. They promote a clean melt by trapping non-metallic impurities and help in maintaining consistent alloy chemistry. Jagannath Company's specialized formulations Cover Flux-11, Cover Flux-05, and Cover Flux-88 are trusted for their superior coverage and dross-reducing capabilities.

Cover Flux-11

Cover Flux-11 is designed for general-purpose use across a broad range of aluminium melting operations. It is suitable for standard aluminium alloys and foundry applications where consistent metal cleanliness is required.

- Usage: Used in re-melting operations, die-casting units, and general aluminium foundries.

- Key Benefits: Excellent dross separation, consistent covering effect, and minimal metal loss.

- Best For: Foundries handling standard and medium-grade aluminium alloys.

Cover Flux-05

Cover Flux-05 is specially formulated for high-silicon and high-magnesium aluminium alloys, providing superior oxidation resistance and excellent impurity entrapment. Its low-slag generation makes it ideal for complex alloy systems.

- Usage: Perfect for aluminium extrusion plants, casting units handling high-silicon alloys, and recycling plants dealing with challenging melt chemistries.

- Key Benefits: Superior oxidation resistance, minimal slag formation, and enhanced metal cleanliness.

- Best For: Aluminium extruders, high-performance casting facilities, and alloy refiners.

Cover Flux-88

Cover Flux-88 is a specialized grade designed for the most demanding melting conditions, including high contamination levels and continuous casting operations. It offers maximum metal protection and impurity capture, ensuring high-quality molten metal output.

- Usage: Ideal for re-melting units, continuous casting plants, and processes handling heavily contaminated scrap metal.

- Key Benefits: Maximum impurity entrapment, exceptional oxidation control, and reliable performance in extreme conditions.

- Best For: Large-scale remelting units, continuous casting lines, and facilities working with recycled materials.

Modifier Flux-29

Modifier Flux-29 is a high-performance flux designed to modify the structure of aluminium-silicon alloys, improving mechanical properties and surface finish. This flux enhances the alloy's microstructure, ensuring superior casting quality and reduced porosity.

- Usage: Suitable for hypoeutectic and eutectic Al-Si alloys in sand casting and gravity die casting processes.

- Key Benefits: Improved grain refinement, enhanced ductility, and reduced shrinkage defects.

- Best For: High-quality automotive components, structural castings, and precision-engineered aluminium parts.

Modifier Flux-26

Modifier Flux-26 is formulated to provide effective modification of aluminium alloys with varying silicon content. It optimizes the melt's characteristics by altering the silicon morphology, resulting in enhanced mechanical strength and better surface integrity.

- Usage: Ideal for die casting operations, sand castings, and continuous casting applications where high-quality surface finish is crucial.

- Key Benefits: Uniform silicon distribution, increased toughness, and reduced micro-porosity in castings.

- Best For: Precision automotive parts, complex mould designs, and high-performance aluminium alloys.

Key Features of Our Cover Fluxes:

- Oxidation Control: Forms a protective layer over molten aluminium to reduce oxidation and metal loss.

- High Efficiency: Effective at low addition rates with minimal slag generation.

- Improved Metal Cleanliness: Traps and removes non-metallic inclusions.

- Multiple Grades: Available in Cover Flux-11, Cover Flux-05, Cover Flux-88, Modifier Flux-29, and Modifier Flux-26 to suit diverse melting practices.

- Thermal Stability: Performs reliably across a wide temperature range.

Customization Options

We provide customized packaging and grade selection based on the customer's melting process, alloy type, and furnace capacity. Technical assistance is available for optimal dosage and handling methods.

Application Areas:

- Aluminium Extrusion and Casting Units

- Re-melting and Recycling Plants

- Die-Casting and Foundry Operations

- Aluminium Alloy Refinement

Protect Your Melt with Confidence

With Jagannath Company's Cover Fluxes and Modifier Fluxes, ensure superior melt protection, improved cleanliness, and better process economics. Ideal for a wide range of aluminium alloy applications and melting setups.

Contact Us

Company: Jagannath Company

Email: jagannath.company@yahoo.com

Phone: +91-98733 84650