Top Ceramic Foam Filters Supplier in India | Jagannath Company

Oct-11-2025

In the world of metal casting, quality is king. Every step in the casting process impacts the final product’s durability, performance, and appearance. One vital yet often overlooked component is the ceramic foam filter. Acting as the silent guardian in the casting process, ceramic foam filters enhance metal purity, reduce defects, and improve overall efficiency.

With India’s foundry industry expanding rapidly—serving sectors like automotive, aerospace, and infrastructure—the demand for high-quality ceramic foam filters has never been greater. This blog will explore the importance of ceramic foam filters, what makes a supplier reliable, and why companies like Jagannath Company stand out in India’s market.

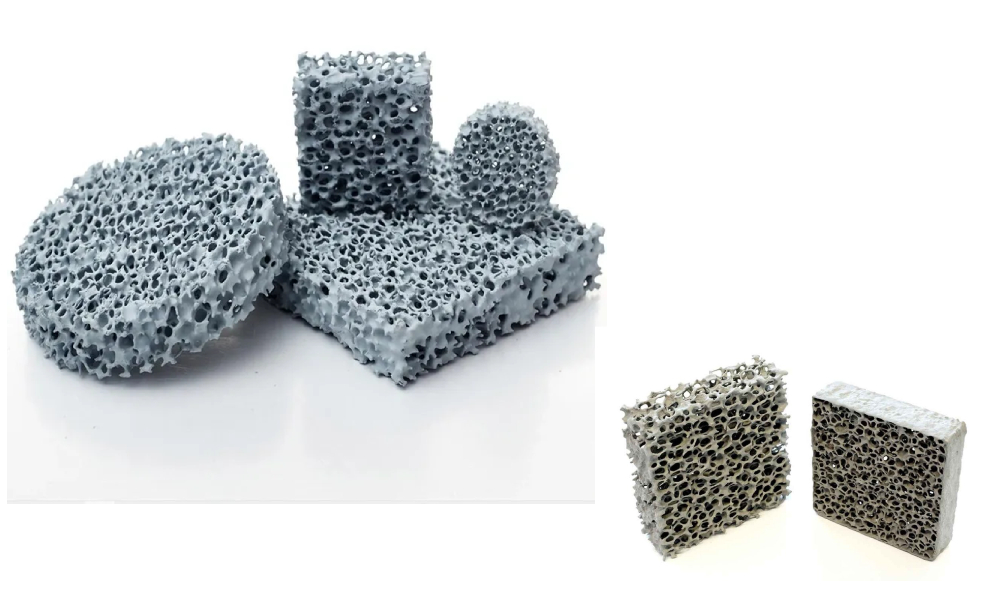

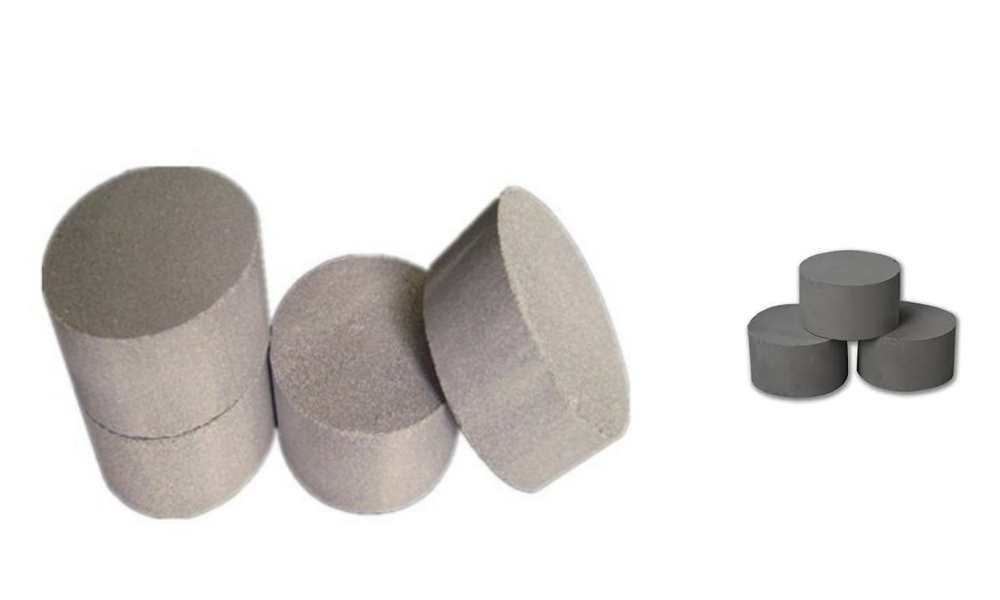

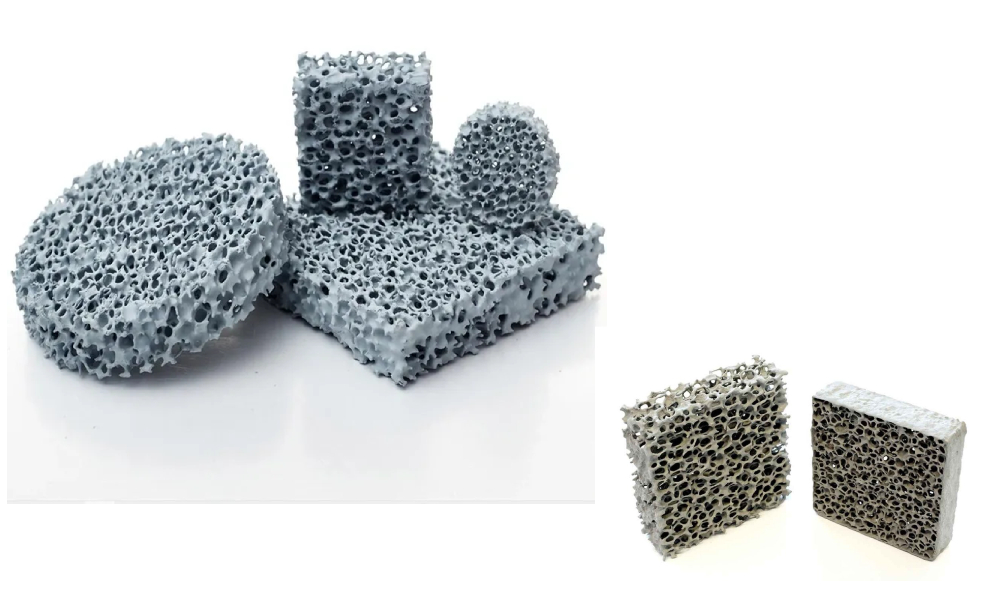

What Are Ceramic Foam Filters?

Ceramic foam filters are porous structures made from materials like alumina, silicon carbide, or zirconia. Their cellular foam design creates a network of interconnected pores through which molten metal flows during casting. These pores act as sieves, trapping impurities such as slag, oxides, and other non-metallic inclusions, ensuring cleaner metal reaches the mold cavity.

This filtration improves:

- Metal purity and mechanical strength

- Surface finish of castings

- Reduction of casting defects like porosity and slag inclusions

- Consistency in the casting process

Ceramic foam filters are especially critical in aluminum, cast iron, steel, and superalloy castings where the quality of the metal directly affects the end product’s functionality.

Why Ceramic Foam Filters Are Essential in Metal Casting

When molten metal is poured into molds, it often carries impurities from the melting furnace. These inclusions can cause defects like blowholes, pinholes, cracks, or poor surface finish. Ceramic foam filters help to:

- Reduce Turbulence: By smoothing the metal flow, they prevent turbulence that traps gas bubbles and creates voids.

- Trap Inclusions: The porous structure filters out unwanted particles that can weaken the casting.

- Increase Yield: Fewer defects mean less scrap and rework, saving time and cost.

- Improve Mechanical Properties: Cleaner metal results in stronger, more reliable cast components.

Growing Demand for Ceramic Foam Filters in India

India’s foundry sector is booming. From manufacturing millions of automotive components to critical aerospace parts, the industry demands superior casting quality. This trend drives the need for advanced filtration solutions.

Several factors contribute to this rising demand:

- Automotive Industry Growth: India is one of the largest auto manufacturers globally. High-quality filters ensure defect-free engine blocks and other components.

- Export Market Standards: Indian foundries supplying to Europe, the US, and Japan must meet stringent quality norms, pushing the adoption of premium filtration products.

- Infrastructure Projects: Durable castings for construction and heavy machinery require reliable filtration.

- Cost-Effectiveness: Reducing waste through better filtration is a smart economic move.

What to Look For in a Top Ceramic Foam Filter Supplier in India

Choosing the right supplier can impact your casting results and overall efficiency. Here are the critical factors:

1. Material Quality

Look for suppliers offering filters made from high-purity alumina or silicon carbide to withstand the high temperatures of molten metal and provide effective filtration.

2. Range of Pore Sizes

Different casting applications require different pore sizes, typically ranging from 10 to 40 pores per inch (PPI). A good supplier offers variety to match your specific needs.

3. Customization and Technical Support

Every casting setup is unique. Suppliers that provide technical consultation, custom sizes, and shapes ensure optimal filtration performance.

4. Quality Certifications

ISO certifications and adherence to international standards reflect reliability and consistent quality.

5. Timely Delivery and Service

Reliability in supply chain and responsive customer service can save you costly production delays.

Jagannath Company: A Leader Among Ceramic Foam Filter Suppliers

Among the trusted names in India’s ceramic foam filter market, Jagannath Company stands out for its commitment to quality, innovation, and customer satisfaction. Known for manufacturing high-performance filters tailored to diverse metal casting needs, the company combines cutting-edge technology with expert craftsmanship.

Jagannath Company’s filters are praised for consistent pore structure, excellent thermal stability, and superior mechanical strength. Their technical team works closely with clients to provide customized solutions that improve casting yield and quality, making them a preferred supplier across automotive, aerospace, and heavy industries.

Applications of Ceramic Foam Filters

Automotive

Used in engine blocks, cylinder heads, transmission casings, and other critical components to ensure defect-free castings.

Aerospace

Filters help produce superalloy parts with high precision and integrity for aircraft engines and structures.

Heavy Machinery

Machinery parts exposed to stress and wear demand castings free of inclusions to maintain strength and longevity.

Electrical and Electronics

Clean metal castings for connectors and housings improve performance and reliability.

Benefits of Using Premium Ceramic Foam Filters

- Higher casting quality and fewer defects

- Improved mechanical properties like tensile strength and fatigue resistance

- Enhanced surface finish, reducing machining costs

- Reduced waste and rework, leading to cost savings

- Environmental benefits from decreased scrap metal

Three Keywords Used in This Blog

- Ceramic foam filters India

- Metal casting filters supplier

- High-quality ceramic filters

Frequently Asked Questions (FAQs)

1. What materials are ceramic foam filters made from?

Common materials include alumina, silicon carbide, and zirconia. Each has specific properties suited for different metals and casting temperatures.

2. How do ceramic foam filters improve metal casting quality?

By filtering out impurities and reducing turbulence, they minimize defects such as porosity, slag inclusions, and improve surface finish.

3. Can I get customized ceramic foam filters?

Yes, many suppliers offer filters tailored to specific dimensions, pore sizes, and metal casting requirements.

4. Are ceramic foam filters reusable?

No. Due to thermal stress and contamination, ceramic foam filters are designed for single use only.

5. Which industries commonly use ceramic foam filters?

They are extensively used in automotive, aerospace, heavy machinery, and electrical component manufacturing.

Conclusion

In an industry where precision and quality dictate success, ceramic foam filters are indispensable tools for metal casters. India’s foundry sector’s growth has made these filters more critical than ever.

When selecting a supplier, prioritize quality, customization, and service. Companies like Jagannath Company exemplify these qualities, delivering products that enhance casting efficiency and reliability.