Top Aluminium Degassing Tablets Manufacturer in Delhi

Aug-8-2025

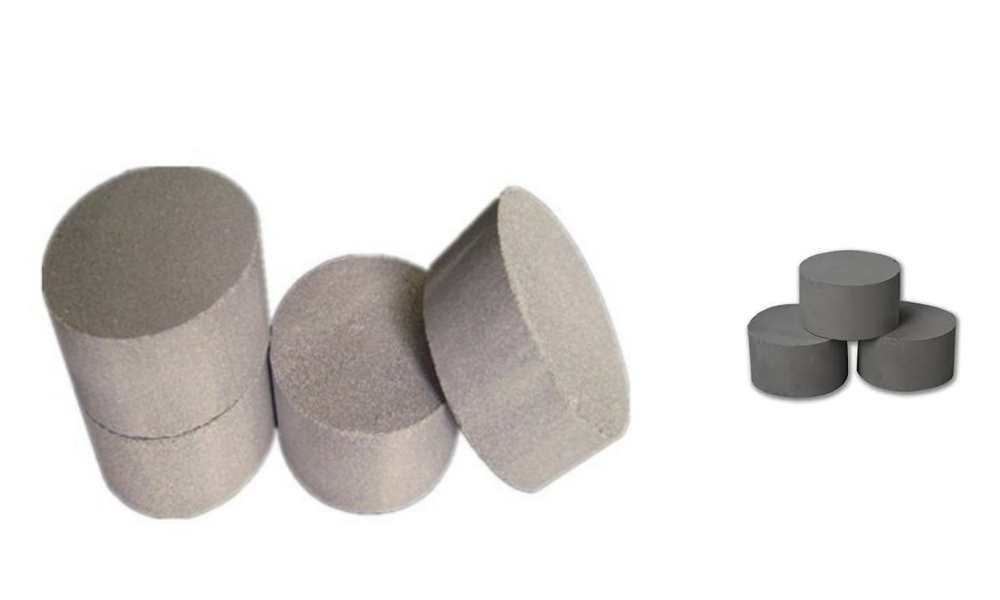

Best Aluminium Degassing Tablets Brand in Delhi

Aluminium casting is an intricate ballet of chemistry, accuracy, and timing. At its molten zenith, aluminium is bursting with promise—but also with vulnerabilities. Dissolved hydrogen and undesirable inclusions compromise the integrity of the metal, which in turn impacts everything from mechanical strength to surface finish.

The answer? Aluminium degassing tablets—technology that has gone largely unnoticed but has revolutionized the casting sector. Whether you're a foundry operator in Delhi or elsewhere in India, such tablets are not merely a piece of equipment; they are critical to casting excellence.

What is Aluminium Degassing: Revolutionizing Foundries

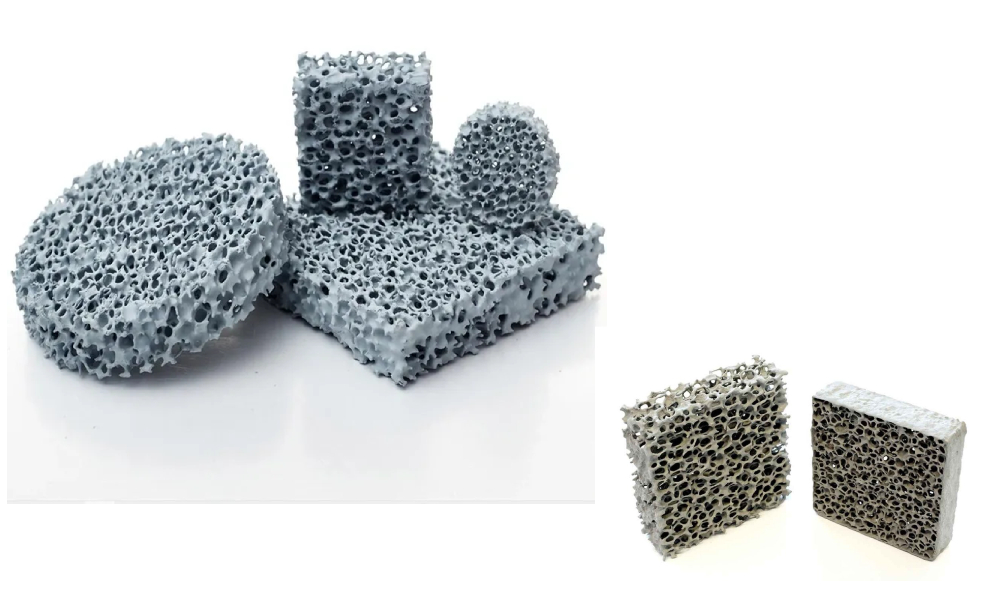

When molten aluminium is contaminated with water or moisture, it takes up hydrogen gas. This hydrogen dissolves in the molten metal but forms bubbles when it solidifies. The outcome is porosity—very small holes that weaken your finished product's quality, strength, and reliability.

Aluminium degassing refers to the elimination of this hydrogen prior to the metal becoming set. Perhaps the most effective, cost-efficient means of doing so is with casting tablets, which are specifically designed to emit inert gases that trap and eliminate hydrogen and other contaminants.

Why Degassing Tablets?

1. Rapid Hydrogen Removal

These tablets are made to work quickly. When they are submerged in molten aluminum, they emit gases that absorb and react with dissolved hydrogen, which floats to the surface and vents. The outcome? Cleaner, more durable castings with less imperfection.

2. Cleaner Metal, Better Products

Hydrogen is not the sole offender. Molten metal is frequently contaminated by non-metallic inclusions (such as oxides or dross). Degassing tablets assist with bringing such inclusions to the surface, enhancing melt cleanliness and surface finish overall.

3. Safe and User-Friendly

Contemporary tablets are made with safety in mind. They're non-toxic, safe to handle, and produce very low fumes while in use—making them an intelligent option for foundry efficiency and operator health.

4. No Need for Gas Injection Systems

Degassing tablets are a low-maintenance alternative to argon or nitrogen purging systems. No extra equipment. No complex setup. Just drop the tablet into the melt and let chemistry do the work.

Jagannath Company: Delhi’s Trusted Manufacturer

When it comes to sourcing degassing tablets, consistency and quality are everything. At Jagannath Company, we’ve built a reputation for providing foundries with top-grade aluminium degassing tablets that are:

- Formulated with precision recipes for optimal hydrogen and inclusion removal

- Available in a range of sizes: 50g, 100g, 250g, 500g, and custom sizes

- Compatible with every type of aluminium alloy and melting facility

- Shipped on time, always—with quality control you can trust

We've assisted foundries all over Delhi and northern India to lower rejections on casting, enhance finish, and increase strength—one tablet at a time.

Applications Across Industries

Degassing tablets aren't specific to one application. They're highly versatile and used extensively in:

- Die Casting Shops – to remove porosity prior to mold injection

- Extrusion Foundries – for ensuring billet quality consistency

- Aluminium Recycling Plants – to degas reclaimed metal

- Sand Casting Operations – guaranteeing clean, blemish-free pours

- Automotive Component Casting – where strength and consistency are most important

Wherever aluminium is being melted and formed, casting tablets assist in providing improved performance.

A Closer Look at the Benefits

Fewer Casting Defects

Porosity, shrinkage holes, and inclusions all become much less common, enhancing casting yield and minimizing waste.

Improved Surface Finish

Fewer impurities in the melt mean a smoother, more machinable surface—ideal for parts that require close tolerances.

Greater Mechanical Strength

Clean metal directly equates to stronger parts, particularly where they're subjected to loads.

Less Downtime

Tablets make degassing easy—no requirement for long nitrogen purging or complicated equipment upkeep.

Enhanced Worker Safety

Low-emission, non-chlorine tablets limit dangerous emissions and make workplace handling procedure easier.

Impact in the Real World

Picture your crew working a complete shift, casting dozens of components an hour. Minutes matter. With conventional techniques, degassing could be laborious or unreliable, causing inconsistent quality. But with appropriate aluminium degassing tablets, the operation is fast, even, and predictable—resulting in fewer rejects and a smoother process.

For companies operating on narrow production schedules or export commitments, that predictability is gold.

How to Use Degassing Tablets Effectively

- Heat the Metal to the Right Temperature: Have molten aluminium at the right temperature.

- Submerge the Tablet: Pour the tablet into the melt with a plunger or mesh basket.

- Stir Carefully: Have the gases disperse evenly throughout the melt.

- Wait and Remove the Dross: Allow the impurities to float and skim off the dross layer.

- Pour as Normal: Continue casting the purged, degassed metal.

Always use precise dosing according to your melt size and alloy type.

FAQs: Aluminium Degassing Tablets

1. How long does a tablet take to work?

The majority of tablets dissolve and function within 1–3 minutes, subject to melt size and temperature.

2. Are tablets safe for indoor use?

Yes, they are low-fume and non-toxic, which makes them perfect for indoor or semi-enclosed foundry operations.

3. Do I still have to use nitrogen gas?

No. These tablets emit inert gases within the unit, doing away with the requirement for individual nitrogen or argon purging systems.

4. Are there tablets for different aluminium grades?

Yes. Various alloys might deserve customized formulas. Ensure you inquire for the appropriate match according to your application.

5. What's the shelf life of the tablets?

When kept in a dry, cold place, tablets last between 12 and 18 months.

Conclusion: Cleaner Metal, Smarter Foundry Operations

If efficiency, safety, and reliability matter to your foundry, aluminium degassing tablets must be an integral part of your cast process. They're small but mighty—designed to streamline your operation and get the most out of every pour.

Delhi foundries have long relied on human skill, but in today’s competitive landscape, technology like degassing tablets brings a powerful edge. And when that technology is locally manufactured, tested, and backed by experience—it becomes a trusted partner in your production line.