Aluminium Foundry Flux Manufacturer

Aluminium Foundry Flux for High-Quality Aluminium Casting

Aluminium foundry flux is an essential material used in aluminum melting and casting operations to achieve clean, defect-free, and high-performance aluminium products. With the rapid growth of aluminium consumption in India and international markets, foundries are continuously looking for reliable solutions to improve melt quality, reduce metal loss, and enhance production efficiency. Aluminium foundry flux plays a crucial role in meeting these requirements.

From small-scale aluminium utensil manufacturers to large extrusion plants and die-casting units, aluminium foundry flux is widely used across multiple industries. Its application helps maintain consistent quality standards while supporting cost-effective and sustainable aluminum processing.

What Is Aluminum Foundry Flux

Aluminium foundry flux is a specially formulated chemical compound added to molten aluminium during the melting or holding stage. Its primary purpose is to remove impurities such as oxides, non-metallic inclusions, and unwanted contaminants from the molten metal. The flux reacts with these impurities and separates them from the aluminum, resulting in a cleaner and more refined melt.

In addition to cleaning, aluminium foundry flux also protects molten aluminium from oxidation by forming a thin protective layer on the metal surface. This significantly reduces metal loss and improves casting performance.

Importance of Aluminium Foundry Flux in Aluminum Processing

Aluminium is highly reactive at high temperatures and tends to oxidize quickly during melting. Without proper treatment, this oxidation leads to excessive dross formation, porosity, and surface defects in cast products. Aluminium foundry flux helps control these issues effectively.

By using high-quality aluminium foundry flux, manufacturers can improve metal cleanliness, enhance fluidity, reduce rejection rates, and achieve better mechanical properties in finished aluminium components. This makes the flux a critical input for both domestic and export-oriented foundries.

Types of Aluminum Foundry Flux

Covering Flux

Covering flux is used to protect molten aluminium from oxidation during melting and holding. It forms a protective barrier on the surface of the molten metal, reducing exposure to air and minimizing oxidation losses.

Cleaning Flux

Cleaning flux is designed to remove oxide films and non-metallic inclusions from molten aluminium. It improves melt cleanliness and prepares the metal for casting or further processing.

Drossing Flux

Drossing flux helps separate usable aluminium metal from dross. This type of flux improves metal recovery and reduces waste, making the process more economical.

Refining Flux

Refining flux improves overall melt quality by assisting in impurity removal and supporting downstream treatments such as degassing and grain refinement.

Applications of Aluminium Foundry Flux

Aluminium foundry flux is used across a wide range of industries where aluminium casting and processing are involved. These include aluminium extrusion plants, die casting units, cookware manufacturing, automotive component production, electrical applications, and construction-grade aluminium products.

In India, demand for aluminium foundry flux is strong in industrial regions such as Gujarat, Maharashtra, Tamil Nadu, Karnataka, Haryana, and Delhi NCR. Internationally, high demand exists in the Middle East, Southeast Asia, Africa, and Europe, where aluminium manufacturing continues to expand.

How Aluminum Foundry Flux Works

When aluminium foundry flux is added to molten aluminium, it melts and spreads evenly across the metal surface. The flux reacts with oxides and impurities, binding them together and allowing them to float to the surface as dross.

This process reduces hydrogen absorption, minimizes oxidation, and improves metal homogeneity. As a result, the molten aluminum becomes cleaner and more suitable for producing high-quality castings with fewer defects.

Quality Standards for Aluminium Foundry Flux

A high-performance aluminium foundry flux should have consistent composition, low moisture content, and excellent efficiency at low dosage levels. It should generate minimal smoke and fumes while maintaining compatibility with various aluminum alloys.

For international buyers, consistent quality and compliance with global industrial standards are critical factors when selecting an aluminium foundry flux supplier.

Global Demand and Market Insights

Global demand for aluminium foundry flux continues to grow due to increased aluminum usage in automotive, infrastructure, renewable energy, and packaging industries. Online search trends indicate strong and consistent interest in aluminium foundry flux, aluminum flux, and foundry chemicals worldwide.

High-demand countries include India, the United Arab Emirates, Saudi Arabia, Iraq, Turkey, Vietnam, Indonesia, Egypt, Nigeria, and several European nations. India remains one of the fastest-growing markets due to industrial expansion and government-led infrastructure projects.

Choosing the Right Aluminium Foundry Flux Manufacturer

Selecting the right aluminium foundry flux manufacturer is essential for achieving consistent results. Buyers should evaluate the supplier’s technical expertise, product consistency, ability to customize formulations, and reliability in bulk supply.

An experienced manufacturer not only supplies flux but also provides technical support and process guidance to help foundries optimize their aluminium melting and casting operations.

Packaging and Supply Capabilities

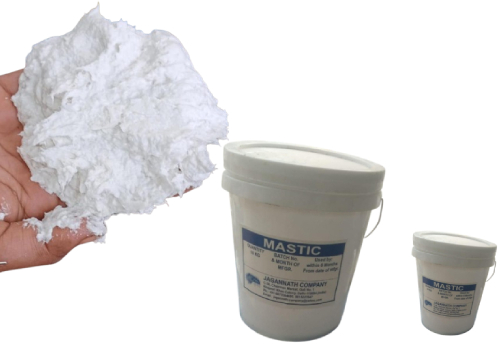

Aluminium foundry flux is typically supplied in moisture-resistant packaging to maintain product stability. Common packaging options include 25 kg bags, jumbo bags, and customized export packaging depending on customer requirements.

Proper packaging ensures safe storage, easy handling, and long shelf life, especially for international shipments.

Environmental and Safety Considerations

Modern aluminium foundry flux formulations are designed to reduce environmental impact and improve workplace safety. Low-smoke and low-fume fluxes help create safer working conditions and support compliance with environmental regulations.

Using efficient aluminium foundry flux also reduces waste generation and improves metal recovery, contributing to sustainable aluminum manufacturing practices.

Conclusion

Aluminium foundry flux is a vital component in achieving clean, high-quality aluminium castings for both Indian and international markets. Its ability to remove impurities, reduce oxidation, and improve melt quality makes it indispensable for modern aluminum foundries.

With growing global demand for aluminium products, the use of reliable and high-performance aluminium foundry flux helps manufacturers improve efficiency, reduce costs, and remain competitive in domestic and export markets.